Posted on May 6, 2025

The Future for Solar is Bright

Author: Tony Giunta, Director of Project Development

Benjamin Franklin once said, “There are only two things certain in life: death and taxes.” While I’m not here to challenge old Ben, I’ve lived long enough to confidently add one more certainty to his list: “There are only three things certain in life: death, taxes, and the sun will rise tomorrow.” With that third certainty comes the opportunity to harness a free source of energy to power our homes, businesses, and planet.

Although the ability to consistently capture an unlimited free power source sounds like a “no-lose” business proposition, the solar industry has always faced stiff headwinds. Its most formidable challenge has been to lower the cost of converting that free energy into a usable form that is competitive with fossil-fueled sources (brown power). This challenge is compounded by the need to navigate the continuously shifting support for politically imposed subsidies designed to “level the playing field” between the comparatively higher cost of green solar and cheaper brown power.

So, knowing that cost is the pivotal factor, can the solar industry ever achieve price equity with brown power? I believe the answer is a resounding yes!

As is typically the case, technology is revolutionizing the solar industry (I’m sure Ben Franklin would appreciate my choice of words here!). Solar photovoltaic panels are becoming more efficient at lower production costs. Five years ago, it cost nearly $4 per watt to produce solar power. Two years ago, that cost was halved to $2 per watt, and today it has halved again to just under $1 per watt.

In terms of cost per kilowatt-hour, ten years ago when Nobis started working with solar developers, the price needed to support a solar project was in the 12-15 cent per kilowatt-hour range compared to 6 cents per kilowatt-hour for brown power. Today, solar developers are building projects with a sale price of 8-10 cents per kilowatt-hour. As you can see (and what should be music to everyone’s ears), solar power is rapidly closing the price gap with its archrival, brown power.

The rapidly falling price of solar really “kills two birds with one stone.” As the price gap narrows, consumers generally choose greener resources. And with that all-important consumer choice, the need for unpredictable and controversial subsidies evaporates. Case in point: solar power is the leading source of renewable power installation in the nation. In 2023, the solar industry set a record by installing 32 gigawatts of solar energy. In 2024, that record was shattered with over 50 gigawatts of US solar installations. Considering each solar gigawatt of power is like building a nuclear-powered facility, the 2023 and 2024 solar installations are equivalent to having built nearly 75 new nuclear power plants, with the added benefit of not having to worry about nuclear waste.

Thanks to advanced technologies, lower equipment costs, and a diminishing reliance on subsidies, the future of solar looks bright (pun intended)!

-->

Posted on September 12, 2024

Achieving Greater Sustainability by Adopting More Energy-Efficient Cycles

By Tony Giunta, Director of Project Development, The Nobis Group

It’s only natural to assume that humans would consume the earth’s natural resources in a sustainable manner. After all, if we fail to live sustainably our species will perish. New Englanders have long understood and practiced this.

In fact, New Englanders have for a long time inherited a reputation of being a very “frugal” bunch. Having been born and raised in this part of the country, I can attest to the fact that we “Yankees” can always find a way to stretch life’s necessities. I truly believe this comes from our early European settler history where one either learned how to sustain food, water, shelter, and even energy – or you didn’t survive the winter! Death, it appears, was an effective incentive for ingenuity when it came to preserving and sustaining resources.

Today, technology provides us with a near inexhaustible supply of life sustaining commodities. So much so, that we no longer give thought during our daily life that wasting our natural resources could result in our demise. So how do we become more sustainable? One way is to consume resources as close to their source location as possible. Although a simple, reasonable, and completely achievable concept, this solution is grossly ignored around the world.

As silly as it may seem, it’s commonplace for raw materials to be shipped thousands of miles only to see manufactured products made from these resources shipped right back to their original points of origin. As a result, enormous amounts of our limited energy supplies are consumed during transit alone.

One example close to home is liquified natural gas (LNG). Because of constrained pipeline capacity during times of heavy consumption, Boston receives LNG shipments from Tobago and Trinidad. At the same time, shipments of the same product are transported from Louisiana to Europe and Asia. The finite fossil fuel resources consumed to power those gigantic LNG transport ships only to deliver LNG are staggering. Enormous amounts of energy could be sustainably preserved if we globally prioritized utilizing energy sources and related raw materials based on their proximity to the user.

Our worldwide energy demands are continuing to rise and, ironically, adding to this is our commitment to build a new generation of renewable energy sources and networks globally. But we need to be just as committed to eliminating our wasteful energy practices at the same time.

At Nobis Group, we are committed to moving our world towards a more sustainable energy future. Over the past decade, remaining steadfast to this commitment has resulted in Nobis having permitted more solar projects than any other firm in New Hampshire. We strive to create a society more reliant on limitless energy supplies like solar and wind power and less reliant on finite energy sources such as crude oil, coal, and natural gas.

-->

Posted on July 18, 2024

No Final Whistle: How Lessons in Teamwork Translate into Environmental Field Work

Author: Stephanie Stone, Staff Scientist

“Herons on three!”, I shouted, almost definitively. It was the last time I would ever say those words, on that field, with the people that I’ve grown the closest to. The end to my field hockey career stung like a heartbreak. Hanging up my jersey marked the end of a chapter I never was quite fully prepared to finish. When you play a sport in college, it becomes your identity, one of your descriptors. Everyone knew me as the field hockey goalie. For over a decade, it consumed my life, and once the final whistle blew, I felt like I was losing a piece of myself.

Sports to Career

Collegiate athletics instilled in me a work ethic that I transitioned into my professional life. They taught me a lot about myself and how to collaborate with those with differing personalities than mine. I created friendships that will last a lifetime. We worked well together on the field, but that did not happen overnight. It took time for us to trust in each other’s abilities, to understand people’s strengths, and to lift them up in times of weakness. The team became a close-knit group that was hard to say goodbye to. I cherish the memories we made and when I look back on my experience, it’s not the wins and losses I remember most, it’s how being a part of that team shaped me into the person I am today.

Challenges in Environmental Field Work

Transitioning into environmental consulting and field work brought its own set of challenges. I promptly learned that field work is demanding – physically, mentally, and technically challenging too. It is a dynamic, fast paced environment where you must anticipate and solve problems on the fly. Much like in sports, success is based on effective teamwork. For these reasons and many others, the work is undoubtedly fulfilling. Environmental field work is by no means a one-person job, even on a seemingly small sampling event. As field staff, we are responsible for interpreting and communicating ever-changing site conditions to our project team members and other stakeholders effectively and frequently.

There is rarely a perfect site, but there are some that are far less than perfect. Your monitoring wells don’t recharge. There are unexpected snow squalls. The equipment you rented loses functionality. Or, most unfortunately, a combination of the three. During these hardships, it is teamwork that will make for a successful field assignment. As field staff, we should be able to lift each other up when challenging situations arise and work together to navigate issues that occur on our job sites. I vividly recall one particularly difficult site last fall in a remote location. Cell service was minimal and the time of year was unforgiving in terms of daylight. Hazardous materials added an extra layer of complexity, requiring constant attention to safety. Yet, through teamwork and resourcefulness, my team managed to surpass every obstacle.

Carrying Sports Values Forward

When I picked up my first field hockey stick, it did not occur to me that the decision would come to shape the rest of my life. We don’t join sports expecting it to land us a job in STEM, but they do instill values that translate in the workforce when it comes time to enter it. Sports change who we are as a person. They teach discipline and cultivate a passion, both favorable qualities to carry into field work. Most importantly, they teach us how to work with others and become valuable members of a team. Fostering a sports team culture in the field can introduce a supportive environment to get a difficult job done. My time as a technical staff member thus far has shown me that, while I hung up my field hockey jersey in 2022, I picked up a new one when I became an environmental staff scientist. I’ve been accepted into a new team, and while I’ve traded in my goalie helmet for a hard hat, I strive to foster the same values that have gotten me this far, just with a different goal. When we work as a team, we win! And for me, there is no final whistle.

-->

Posted on April 22, 2024

EPA’s Superfund Program Turns 44 This Year:

Authors: Pete Delano, PE, Director of Project Development & Scott Harding, PE, Vice President of Business Development

In the early 20th century, industrial activities and improper waste disposal practices led to the accumulation of toxic substances in various locations across the United States, posing a threat to both the environment and public health. To counteract this and reduce future impacts, the United States Environmental Protection Agency (EPA) set forth on a mission to identify and remediate contaminated sites and to hold accountable parties responsible for the costs associated with these clean-ups. Thus, in 1980, the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) was born – more commonly known as the “Superfund”.

How does it work?

The Superfund has served as the primary Federal regulatory mechanism to address hazardous waste sites across the United States, responding to potential environmental human health risks from abandoned or uncontrolled hazardous waste sites in cooperation with States and Tribal Nations. It is a complex process that can be broken down into six primary steps:

- Site Discovery and Assessment: Often, this phase begins with a notification to EPA by a local or State agency of a potential or actual spill, leak, or release, followed by EPA conducting a brief site inspection and some limited initial sampling to determine if regulated hazardous materials are present and to establish the severity of potential risks to human health and the environment.

- Placement on the National Priorities List (NPL): During this phase, EPA will conduct a pre-CERCLA screening, more site sampling and investigation is completed to establish the nature and extent of contamination further, and the site is ranked and prioritized against other hazardous sites that qualify for Superfund resources and efforts.

- Remedial Investigation/Feasibility Study (RI/FS): This stage involves an evaluation of the nature and extent of contamination at a site and assessing risk to human health and the environment. This stage of the process also includes evaluation of the potential performance and cost of the remedial options identified for a site.

- Records of Decision (ROD): The ROD explains which cleanup alternatives will be used at NPL sites. Leading up to the issuance of the ROD, the EPA recommends a preferred remedy and presents the cleanup plan in a document called a Proposed Plan for public comment.

- Remedial Design/Remedial Action: Detailed cleanup plans are developed and implemented during the remedial design/remedial action (RD/RA) stage. Remedial design includes development of engineering drawings and specifications for a site cleanup. Remedial action follows design and involves the actual construction or implementation phase of site cleanup.

- Post Construction Completion: Activities undertaken during this phase help ensure that cleanup work at a site continues to protect human health and the environment. Work can include routine monitoring of a site; routine reviews of the site to ensure cleanup continues to be effective; and enforcing any long term site restrictions.

EPA’s goal is to make sure site cleanup is consistent with the likely future use of a site. Consideration of reuse at a site can occur at any point in the Superfund cleanup process, from site investigation activities to deletion from the NPL. EPA works with communities to make sure sites or portions of sites are used safely.

Throughout the CERCLA process, EPA relies on a pool of engineering and environmental firms to conduct this CERCLA work that have been deemed to be qualified as having the necessary engineers, geologists, scientists, chemists, toxicologists, and other related CERCLA expertise.

So, who funds the Superfund?

The EPA has had success seeking out responsible polluters to perform or fund their site cleanups – in 2023 alone, the EPA’s enforcement actions resulted in more than $900M in responsible party commitments, further helping to fund needed cleanups. But what happens when a responsible party can’t be identified or in situations like natural disasters where no one can be held responsible to foot the bill? In those cases, the EPA must rely on additional funding.

For instance, in 2021, the Bilateral Federal Infrastructure Investment and Jobs Act (IIJA) assigned $3.5B to the EPA’s Superfund program. On top of this, the long-discontinued Federal petroleum tax was reinstated. This is a reinstated Federal excise tax placed on every gallon of gasoline and diesel fuel sold in the US and is expected to generate more than $50B in revenue over the next 10 years, potentially allowing the Superfund program to accelerate many more site cleanups well into the future.

What does the future hold?

Over the years, the Superfund has made significant progress in cleaning up contaminated sites and protecting communities. Thousands of sites have been addressed and successful cleanups have led to the revitalization of once-polluted areas. The Superfund program has not only improved environmental quality, it has enhanced public health and safety.

Since 1980, 457 sites have successfully been deleted from the NPL. Today, about 1,335 sites remain and about 1,242 sites are considered substantially “Construction Complete”, according to data published by the EPA.

Moving forward, the EPA has stated that their plans and priorities to evolve the Superfund’s future priorities are as follows:

- exploring the potential for beneficial reuse of rehabilitated sites to construct solar, wind, and other renewable energy projects;

- adapting Superfund site cleanups to account for climate change;

- establishing environmental justice criteria to prioritize selected site cleanups;

- and continuing to focus on new and emerging contaminants including PFAS (per- and polyfluoroalkyl) substances, microplastics, pesticides, pharmaceutical wastes, and other chemical-based products.

Since its inception, the EPA’s Superfund has certainly experienced ebbs and flows in its funding, progress, priorities, and political pressures. But overall, its primary mission remains the same today as it has for over forty years: protect human health and the environment, make responsible parties pay, involve communities in the process, and ultimately return Superfund sites to productive use. The work is complex and it can take many years to navigate the entire CERCLA process, but it’s a critically important effort towards improving the communities we live in now and for generations to come.

-->

Posted on April 11, 2024

Unlocking the Artistic Side of Engineering

Author: J. Christopher Nadeau, PE – Director of Commercial Services | Associate

Despite the stereotype of a typical engineer as being calculated and precise, most engineers have a creative side with an ability to cross the boundaries of mathematics and science.

Growing up with a parent who was an avid landscape artist, I have always had a passion for drawing and painting. I took art classes throughout my years of school and University, but never really considered myself good enough to pursue it further. My drive to pursue a career in engineering and raising a family caused that interest to take a back seat. Now that I’m getting on in my years, I think about revisiting that original passion.

I attended a national conference for engineering companies back in October where I heard a speaker talking about the advancement of STEM (Science, Technology, Engineering, and Math) by adding Arts to make STEAM. I never considered incorporating Arts into my engineering role, but it makes sense. There is an artistic side to what we do every day, from incorporating creative elements into writing reports to creating site designs. Harnessing your artistic side allows you to think outside the box and to look at something different than the standard, rigid rules of engineering.

Setting aside my own personal interests, I have been thinking about how Nobis Group and other companies can incorporate the arts into our workplace cultures because we all realize that recruitment and retention of engineers remains one of the top industry concerns post-COVID. A shortage of engineers will remain for many years and we are burning out our existing talent.

So, how can we set ourselves apart from other equally qualified engineering firms to recruit new talent? By incorporating Arts into our company values that support and encourage employees to pursue their passions in Music, Acting, Drama, Visual Art, Creative Writing, and more. This could entail taking a class, adding a weekly social to our schedule to celebrate co-workers’ artistic talents, having a company event at an art gallery, or even a musical concert.

While writing this article, I interviewed a potential mid-level engineering candidate (something we call a “unicorn”). I asked what their interests were outside of work and not surprisingly they said they were an avid musician prior to entering the engineering world. But, like many, decided that music would not pay the bills, so a career in engineering was much more practical. A familiar decision many of us have faced.

Where do we go next? Personally, I need to carve out time in my schedule to pursue some bucket list items: travel, learning a new language, and enrolling in drawing/painting classes. Next, I need to set goals and finally sign up for a class or two. From a company perspective, it is important to poll and listen to employees to understand the breadth of their interest in the Arts and creative opportunities to celebrate and encourage their interests. Let’s blend the worlds of STEM with the Arts to spark creativity and innovation within the engineering industry. Full STEAM ahead!

-->

Posted on May 17, 2023

New England’s Affordable Housing Shortage – Don’t Forget Our Seniors!

Authors: Peter Delano, PE – Senior Vice President | Associate & J. Christopher Nadeau, PE – Director of Commercial Services | Associate

We’ve all seen the news reports and articles explaining the need for more affordable housing choices in Massachusetts, and throughout all of New England, for that matter. Over the past several years, Millennials (those born between 1980-1994) have bought up a record number of homes due to year-after-year, ultra-low interest rate mortgage loans; and Generation Z (born 1995-2015) is now faced with greatly increasing housing costs and high rental rates against a low inventory. On top of all this, the Baby Boomer Generation (those born between 1946-1964) are now retiring at a rapid pace and seeking out a wide variety of senior housing options as well.

In Massachusetts alone, a shortage of more than 100,000 housing units was forecasted in 2022. When it comes to the aging “boomer” population’s housing needs, the issues that lie ahead are not “just” affordability and quantity. The challenge is much more complex. We must provide, with urgency, a solution for the very unique housing needs that our seniors will require at an ever-increasing rate: Continuing Care Retirement Communities (CCRCs).

A CCRC can be defined broadly as a community that offers a full range of long-term housing, healthcare, and essential community services and amenities to its senior residents in a setting where their changing needs over time can be accommodated without having to move to a different facility or community. Also referred to as “aging in place” communities, this is what the majority of senior citizens desire most according to the American Association of Retired Persons (AARP). And these “aging in place” communities are needed in both urban and suburban areas alike.

FIRST, THE NUMBERS:

By 2030, all Baby Boomers will be at least 65 years old. By 2034, the 65+ population will outnumber the number of children in the U.S. and the 85+ population will double from what it is today. Today, the 65+ U.S. population totals about 60 million and, by 2030, this number is expected to reach more than 71 million. These numbers illustrate how critical the need is to provide a massively increased number of CCRCs throughout New England.

Let’s take a look at some important site planning features that Planners, Architects, and Engineers must consider and incorporate into their design of these unique “aging in place” communities:

HOUSING UNIT FLEXIBILITY & CHOICE:

CCRCs should offer a mix of housing options including apartment rentals, condominiums, and detached/attached housing units. First floor and ADA accessible living, small-sized units, covered parking/garages, and additional space for live-in home health care aids, as well as the flexibility to move into different types of housing units within the CCRC as residents age are all critical considerations during planning and design.

AMENITIES:

Key CCRC amenities that must be accounted for in planning and design are access to healthcare, shared dining options, and social/recreational activity areas. Many CCRCs provide on-site healthcare clinics, dining halls, clubhouses, pool complexes, and more. The ability to provide these amenities requires an on-site workforce, workforce parking, and, oftentimes, additional related buildings and structures. Ease of access, wheelchair and mobility scooter access, and proximity to housing within the CCRC must be carefully accounted for during the site planning phase.

WELLNESS:

Promoting resident health and wellness and providing access to natural light with indoor and outdoor spaces for socialization and exercise are important site design features for an “aging in place” community, especially with quarantining and social distancing protocols that may still be in effect from the COVID-19 pandemic. Many CCRCs also offer specialized care for seniors affected by Alzheimer’s and other types of dementia including circular winding walking pathways, with a focus on sufficient site lighting, proper fencing, and carefully designing all pedestrian-vehicle interface areas.

SAFETY & ACCESS:

Site design layout for access into and throughout a CCRC must also carefully account for vehicle parking for visitors, employees, care providers, senior van shuttles, ambulances, and other emergency services. Design considerations for community access and exit points, whether to have controlled gated access or not, and having an accessible location and process to safely control and receive visitors are all critical design considerations for CCRCs and their residents.

Continuing Care Retirement Communities are not just a solution to our current “boomer” population’s critical housing needs – these communities are a long-term investment in the future of all generations, providing choice, independence, and dignity when it comes to aging in a safe, affordable, and supportive long-term housing community.

The effort to provide thoughtfully designed aging in place communities requires many key stakeholders to come together: our community leaders, elected politicians, developers, real estate professionals, and, of course, the Architecture & Engineering industry.

So, let’s get going because we’re not getting any younger.

-->

Posted on November 17, 2022

Contaminated Soil Management in Massachusetts – Plan Ahead and Plan Carefully!

Author: Jeffrey Brunelle, CPG – Director of Project Development

In Massachusetts, it’s becoming increasingly challenging to manage excess soil generated during construction that requires off-site disposal. Today, there are fewer facilities that will accept soil for disposal within the Commonwealth. Contaminated material exceeding the Reportable Concentrations as promulgated by the Massachusetts Department of Environmental Protection (MassDEP) typically must be disposed out of state.

Disposal restrictions and increasing costs often have big impacts on the overall project budget and schedule, so early soil management planning is imperative to the smooth execution of a construction project that includes earthwork and off-site soil disposal.

Plan for Soil Management

It’s important that consultants explain and educate their clients early on that soil disposal is complex and that contamination can be encountered even on supposedly clean sites. Often clients don’t include soil disposal in the budget, as they may assume sites with no evidence of historical contamination to be clean; however, even assumed clean sites may still have stringent disposal requirements.

It’s very rare to have soil, especially from urban sites, that is deemed to be acceptable for unrestricted use. Even marginally contaminated soil or soil with compound concentrations less than MassDEP reportable concentrations require some special handling and disposal to ensure that contamination is not inadvertently spread to a new location.

Soil characterization and disposal costs can very easily and quickly grow significantly, depending on the volume of soil and compounds encountered in the soil. And it’s through effective soil management planning that one can best avoid costly change orders or unplanned costs related to soil management and disposal.

Soil Testing

Soil to be moved off-site needs to be sampled for a robust analytical suite to identify reuse and disposal options. The number of samples to be collected depends on the volume of soil to be disposed and the permit requirements of the licensed disposal facility. In addition, facilities may also have specific acceptance criteria outside of analytical testing, such as requirements for soil field screening using an Photoionization Detector (PID) or observation of soil excavation by a certified environmental professional.

Analytical data will be compared to disposal facility acceptance criteria to establish available off-site disposal options. Facility acceptance criteria varies from facility to facility and is based on the facility’s operating permit. Permit requirements are often based on a facility’s processes and location.

There’s Liability with Testing

Whenever you collect analytical samples, results are subject to comparison to the MassDEP standards promulgated in the Massachusetts Contingency Plan (MCP). Data that exceeds the MCP Reportable Concentrations requires MassDEP notification and contaminant remediation under the MCP.

Projects tracked by MassDEP under the MCP can be costly and time consuming. Be sure that your project plans warrant soil sampling prior to sample collection to limit potential cleanup liability under the MCP.

Think About Your Soil Management Options

Can soil be reused on-site? If so, soil sampling may not be warranted. Is in-situ soil characterization or stockpile profiling more appropriate for your project? Pre-characterization of in-situ soil can be helpful for budgeting purposes; however, this approach does not guarantee that pre-characterized soil is always representative of actual soil to be disposed. Characterization of stockpiled soil that has been excavated is always more representative, but unknown costs, schedule, and facility selection implications may be unknown until the time of sampling. Also, there’s not always adequate physical space on a jobsite to store and manage stockpiled soil.

These soil assessment management implications should be discussed with the project team early in the job process to find which method will work best for your project. Soil management plans should be documented within the project specifications and in a Soil Management Plan for unregulated sites or a Release Abatement Measure Plan (RAM Plan) if the Site is tracked under the MCP.

Acceptance for Disposal Takes Time

Analytical turnaround times are typically around two weeks due to the robust analytical suite mentioned above and due to the time required for sample analysis. Often analytical results cannot be rushed since some of the analytical processes take a set amount of time (such as extraction for Polychlorinated Biphenyls or metals).

Disposal facility selection may be dictated by the project schedule. There may not always be an earthwork contractor under contract to select disposal locations during the early project phase when soil management decisions are made, so it’s key to make clear upfront who is responsible for this task. Typically, it is the responsibility of the earthwork contractor to select disposal locations, and they are not always present in the project planning phase.

Typically, it is the responsibility of the earthwork contractor to select soil disposal locations; however, the contractor may not be under contract during the early project phase when soil management decisions are made. Facility selection may be dictated by the project schedule, so it’s key to decide upfront who is responsible for this task.

Soil profiles are required by each proposed disposal facility. As mentioned above, acceptance criteria vary from facility to facility. Because of this, facility evaluation can be complicated and take time. Also, the time needed for the disposal facility to review the soil profiles has to be taken into consideration. Often a disposal facility contracts with an environmental firm to review their disposal applications. Understandably, this further adds to the acceptance timeline. Also, if your site is regulated by the MassDEP and is subject to requirements of the MCP, a Licensed Site Professional (LSP) is required to complete the soil profiles and transportation paperwork.

Plan for a month or more for facility acceptance.

Disposal Options

Do some “what if” scenario planning, but always work toward the best disposal option and, again, start this effort early on. Have a contingency plan and back-up facilities for soil disposal. Obviously, as soil volumes and contamination increases, so do the associated disposal costs.

Soil with concentrations consistent with background levels (as defined in 310 CMR 40.0006) typically do not have reuse restrictions since contaminant concentrations are non-detect or extremely low. This type of soil may not generate a disposal cost, but may carry a liability due to potential human health concern risks, as reuse locations could include a school, daycare, or backyard.

Soil classified as hazardous waste carries a high cost of disposal due to the potentially toxic characteristics of this material and the specialized handling and disposal requirements. No in-state facilities are available for hazardous waste disposal, and transport to an applicable disposal facility could be as far as Ohio or Canada.

Unrestricted use and hazardous waste classifications “book end” the wide spectrum of soil management classification. Typically, soil is classified as either impacted soil or contaminated soil. Impacted soil contains compound concentrations greater than background levels, but less than the MCP release notification thresholds. Contaminated soil contains concentrations of contaminants that exceed in-state acceptance criteria and are not classified as a Hazardous Waste.

Impacted soils may be reused at in-state locations such as a MassDEP-permitted reclamation soil project under MassDEP Policy COMM-15-01 or reused as daily cover, intermediate cover, or pre-cap contouring material at in-state unlined or lined landfills under the MassDEP COMM 97 Policy.

COMM-15 facilities require scrutiny for acceptance since acceptance criteria is not universal. COMM-97 acceptance evaluations are easier because the acceptance criteria are universal, as published in the policy documents. Disposal at these in-state facilities can be problematic, as quantities to be accepted may be capped yearly and these facilities do not always operate on a fixed schedule. With varying schedules for operations, these facilities commonly stop accepting waste as they reach their established annual capacity, rendering these disposal options unreliable.

There are no longer any in-state options for disposal of contaminated material, making hauling and disposal costly under this soil category. Also, impacted soil may be managed as contaminated soil (and carry a higher premium as such) as disposal options for impacted soil become no longer available.

Consider Soil Reuse On-Site

Another option is to reuse soil that is not grossly contaminated on-site. MassDEP permits on-site soil reuse typically when contaminant concentrations do not pose a significant risk to human health and the environment and reuse of soil will not degrade the soil quality at the site.

The Similar Soils provision prohibits contaminated soil from being moved to a portion of the site that has lesser contaminant concentrations (i.e., a cleaner area of the site), so some site investigation may be necessary to document site conditions for reuse.

Another consideration for site reuse would be geotechnical suitability to ensure the material to be reused on-site meets construction requirements. This brings up a key point – soil contamination is not the only factor that may require off-site disposal. Soil with high debris components may be unusable in construction and therefore would require off-site characterization and disposal.

Conclusion

Soil management considerations as an afterthought are often costly to the project. Disposal costs may vary from as little as $22 per ton for COMM-15 soil to more than $450 per ton for hazardous waste. Remember that economic variables such as cost of fuel, personnel shortages, and supply chain issues each can adversely impact your disposal costs.

Ignoring or delaying soil management planning may result in hefty project change orders and significant project delays. Carry a monetary contingency for soil management evaluations and off-site soil disposal to avoid surprises. Also – your site is never as clean as you think it is. It’s likely going to cost something for off-site disposal of soil you can’t reuse on-site. So, plan ahead and plan carefully!

-->

Posted on October 26, 2022

Using Ground Improvements to Engineer Safer Solutions for Urban Development

Author: Sarah Kurtzer, EIT – Project Engineer

With the rise in construction activity and demand for additional and improved transportation services, the need to utilize sites with unsuitable soil conditions for new construction has increased substantially in the past few decades. Building on these unsuitable soils can result in bearing capacity failures, excessive settlement, liquefaction of soils, sinkholes in roadways, and landslides, to name a few. Previously, very few (and usually costly) methods were available to solve the issues associated with unsuitable soil conditions like uncontrolled fill, soft clays, loose coarse-grained soils, and collapsible soils.

Ground improvement, or ground modification, is the process of using mechanical means to improve the engineering properties of on-site soils. Ground improvement comes in many forms including densification of existing on-site soils, drainage and dewatering, preloading, reinforcement, chemical stabilization, and thermal and biological treatment. Selection of a ground improvement method should consider structural, geotechnical, environmental, and construction conditions, as well as reliability and durability. Some of the more common types of ground improvements are traditional compacting, deep dynamic compaction, rapid impact compaction, aggregate piers, and rigid inclusions.

Ground improvements have become a favorable option as technology has advanced. In many situations, improving the ground is a more economic and more efficient means of making a site suitable for construction. Ground improvements may eliminate the need for costly deep foundation systems such as driven piles, drilled shafts, and micropiles. Disposal costs may also be reduced as most ground improvement methods produce little to no waste, which is extremely advantageous on environmentally impacted sites.

The geotechnical industry is always developing and implementing new ways to work with difficult geotechnical conditions. Ground improvements provide alternative solutions to urban development that can be tailored to each specific site and project.

-->

Posted on October 10, 2022

When Safety and Quality are Critical, Take a Cue from the Nuclear Power Industry

Author: Zachary R. Reed, ASP, CHST – Health & Safety Manager

Human Performance Tools

Do you remember playing “telephone” when you were younger? In a game of telephone, one person begins by whispering a secret phrase into the closest player’s ear. In sequence, each recipient relays the message – as well as they can – to the next person. In the end, the last person exclaims the message they think they heard, and of course it is invariably revealed that the message was horribly confused throughout the chain of players! How could the simple act of repeating a sentence get so badly muddled?

While communication errors may be a reliable way to entertain a classroom full of children, when the stakes are higher, matters of clear communication, and reducing human error generally, can be serious. One does not have to think hard to imagine settings and occupations where human error could lead to disaster – nuclear energy production, manufacturing, railroad transportation, and military applications to name a few. The US Department of Energy claims that about 80% of adverse events are the result of human error. As a safety professional, I am always interested in learning about ways to weed out mistakes – those human errors that can seem so elusive and hard to control – but can result in injury, property damage, and environmental damage just the same as mechanical failures, maintenance problems, and other causes which may seem easier to detect before they become an issue. The game of telephone is an exaggerated example for certain – but any time we undertake tasks with others, the risk of human error from unclear communication or imperfect instruction is a factor. Given such a large percentage of errors may be related to human performance, isn’t it reasonable that we should seek to do whatever we can to reduce their incidence?

One resource that doesn’t get much attention outside of the industries like the ones mentioned above is the concept of Human Performance Tools (HPT). Essentially HPT are a group of behaviors that can be employed – by anyone, whether they be plant personnel, construction workers, or engineers – to reduce the likelihood of undesirable human error events. Sounds good right? When it really matters, any business or organization can use HPT to reduce human error and help critical outcomes succeed. Widely used by the nuclear energy industry, the U.S. Department of Energy has published for public release a two part manual for understanding and employing HPT titled DOE-HDBK-1028-2009, Human Performance Improvement Handbook. In this article we will look at three of the easiest to use and widely applicable tools, that you can use to improve safety, quality, productivity in your organization’s critical endeavors.

Pre-Job Briefings

It may seem simple but taking the time to write a plan – tailored to your activity – – and then discussing it with your team is probably the most impactful thing you can do to reduce human error. In the rush to begin a task or project, this crucial step is often skipped – leading to dangerous or time-consuming mistakes. When conducting your pre-job briefing, include the scope of work, team roles and responsibilities, the sequence of steps, hazards associated with each step, means of controlling each hazard or risk, criteria for when to stop and re-evaluate, and inspection requirements for your tools and equipment. Having a pre-job brief every time you start a task will help all involved better understand the task, and their role. It will help to ensure that needed supplies and equipment are staged and ready to go before the work starts. It will give everyone a chance to ask questions and gain a better understanding of the task which not only improves safety outcomes, but also efficiency, improving your organization’s bottom line.

Consistently conducting pre-job briefings will help prevent complacency, improve efficiency, and combat dangerous or misguided assumptions. Though it may seem obvious, there is good reason that pre-job briefings are a big part of HPT in safety-critical environments. As the adage goes, “those who fail to plan, should plan to fail”.

Three-Way Communication

Remember our game of telephone? Three-way communication is essentially the opposite of that. Three-way communication consists of using three steps to communicate a message (usually instructions) between a sender and receiver, while minimizing the chance of error or misinterpretation. It is equally useful in face-to-face communication as it is in remote communication, where static, lag, or other technological limitations may interfere with clear communication. The three steps to be used are:

1. The sender states their message clearly to the receiver.

2. The receiver repeats the message back to the sender in their own words, however repeating names and labels word-for-word. Paraphrasing in this step allows the sender to evaluate whether the receiver truly understands the message, as opposed to merely repeating what was heard.

3. The sender informs the receiver whether the message was properly understood. When communicating other than face-to-face, using phonetically dissimilar sounding phrases, for example “Yes, that is correct” and “No, that is wrong” as opposed to saying “incorrect” will ensure that the message will be heard correctly even if fragments are lost in telecommunication. If the receiver demonstrates incorrect understanding of the sender’s message, the sender restates the message until proper understanding is confirmed.

Using three-way communication, much like pre-job briefings, is a great way to know if your team knows exactly who, what, when and where must be done, while nipping assumptions and misunderstandings in the bud.

The NATO Phonetic Alphabet

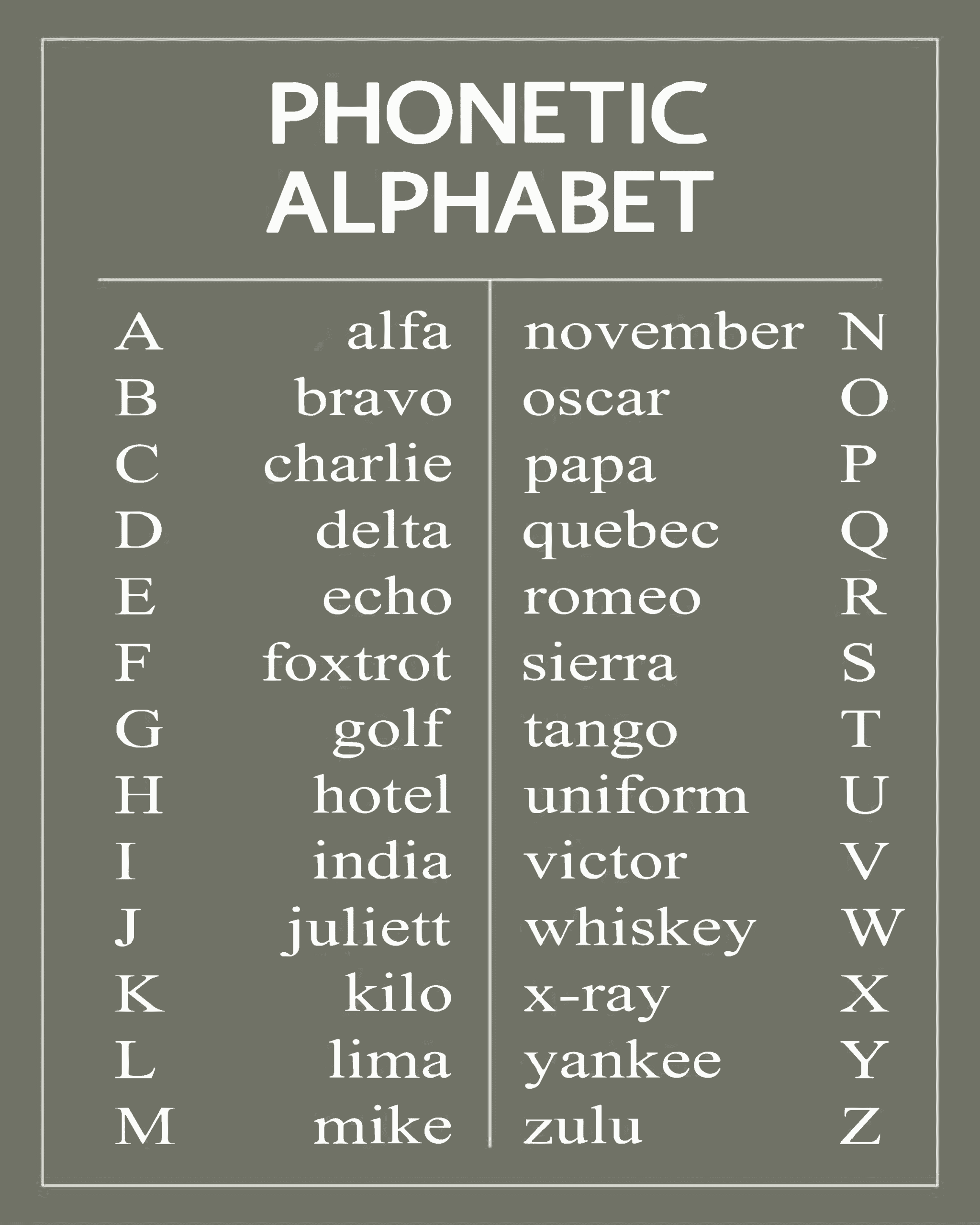

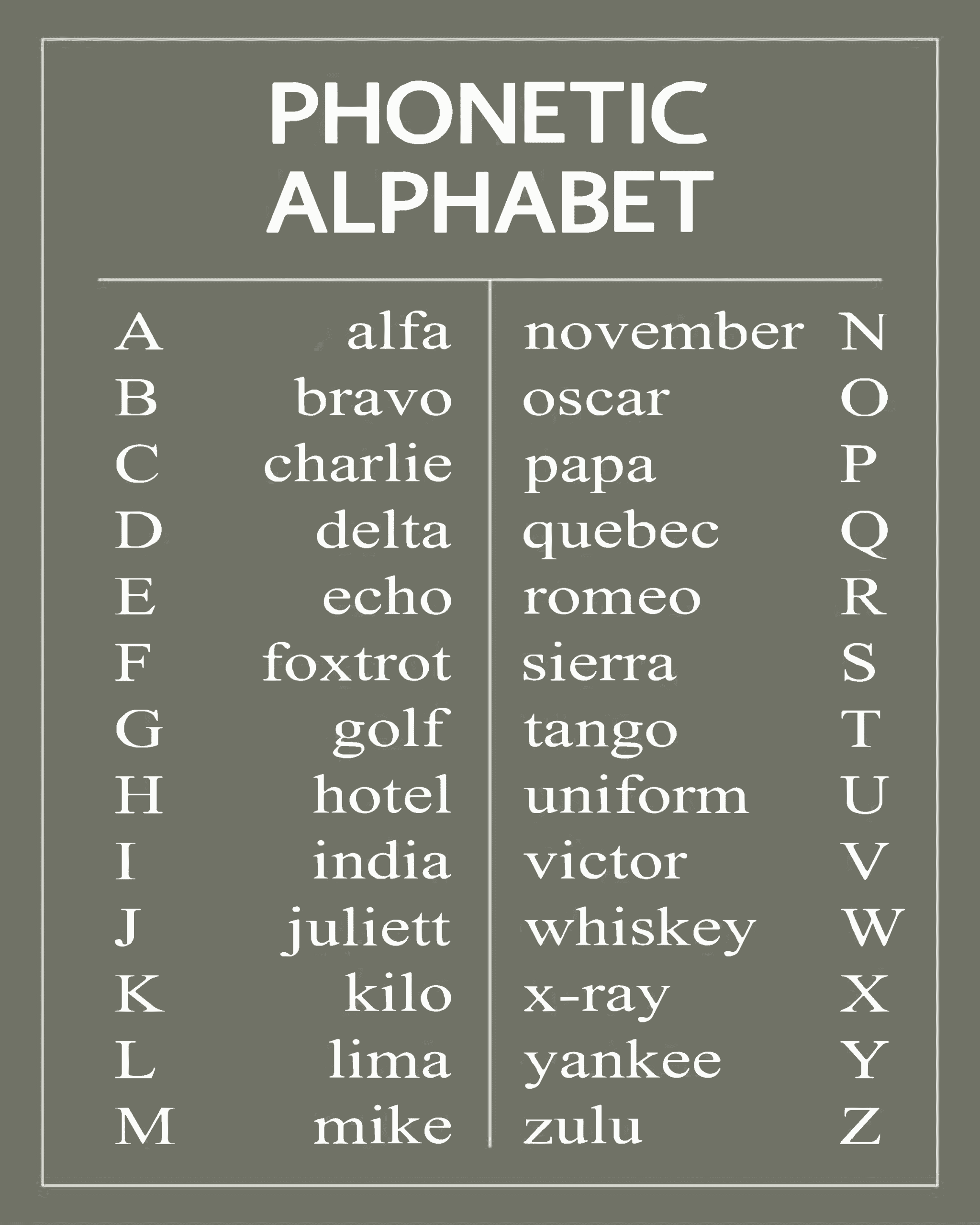

In the early 20th Century, as voice telecommunications becoming commonplace around the world, it became apparent that miscommunication of the spoken names of letters of the alphabet was a new source of human error. When spoken through, for instance radio, it was common for phonetically similar sounding letter names to be confused by the listener. Consider how similar “B”, “D” and “V” sound, or worse yet, “M” and “N”. Various phonetic alphabets, also known as speaking alphabets, were developed by organizations around the world to eliminate these errors by giving each letter a phonetically distinct sounding name.

It wasn’t until 1956 that the NATO phonetic alphabet was adopted in its current form (see sidebar), but it has been the closest thing to a universal standard for many organizations ever since. Taking a little time to memorize the NATO alphabet and use it when spelling or communicating letter names will make your telecommunications more effective and accurate (even if you only use it to spell your email address over the phone). Using agreed upon standards rather than improvised solutions is a theme in HPT. For phonetic alphabet selection, the NATO phonetic alphabet represents the most widely adopted choice.

The NATO Phonetic Alphabet – note the spellings of “Alfa” and “Juliett” are intended to reduce mispronunciation errors across a variety of language users.

Over and Out

This article only described three of the many HPT adopted by the DOE and other safety-sensitive organizations. Much more information regarding strategies for groups and individuals to reduce human error is available in DOE-HDBK-1028-2009, Human Performance Improvement Handbook. The fact is, these and other tools work.

If you aren’t used to them, using HPT can perhaps seem silly or overly serious. Famously, foreign tourists visiting Tokyo, Japan are often perplexed by railroad workers’ constant pointing and calling out seemingly mundane things in and around trains. What tourists may not realize is that these railroad workers are using their industry’s own form of HPT to ensure that routine actions are completed properly and safely. Since its adoption, the system, known as shisa kanko (point and call) has reduced targeted human errors by about 85%. Though shisa kanko may not be useful to your organization, if you accept that human error is widespread, you may find that using some of these tools as well as others found in the DOE handbook, may be worth putting self-conscious feelings aside and implementing in your workplace to mitigate costly human errors.

Human Performance Tools have been developed to eliminate human error where it simply isn’t acceptable. True, there are few things as critical as safely operating a nuclear power plant or operating a commuter railroad. It is up to you and your specific goals with respect to safety and quality in your operations to determine how much risk of error you can tolerate. For those operations where there is simply no room for error, or simply to take a bite out of 80% of your organization’s errors, consider using Human Performance Tools to reduce mistakes.

-->

Posted on August 3, 2022

I Hear a Train a Comin’

Author: Tony Giunta, PG – Director of Project Development

As most of the world is basking in hellish heat and the President contemplates enacting an “Emergency Climate Declaration” to combat global warming, Nobis Group can proudly proclaim that, for the past six years, we have been working with solar developers to permit dozens of clean, zero-emission, renewable energy projects. And although I’m thrilled to be part of a more sustainable energy future, experience has provided me with a disturbing glimpse into the future, and I can’t help but recall some old lyrics by the immortal Johnny Cash:

I hear a train a comin’,

It’s rolling ‘round the bend…

And, from how I see it, just on the other side of that bend are all our renewable energy projects, precariously strewn across the tracks, waiting to be smashed by that ever-approaching train. The train is a euphemism here, of course, and it represents the growing chorus of opposition from those vehemently against renewable energy projects – whenever and wherever proposed. It doesn’t matter whether the community has committed to carbon reduction goals, and it doesn’t matter if these projects are proposed in areas populated by majority Republicans or Democrats, environmentalists or capitalists, global warming believers or deniers. Wherever I go, the message is clear: “Your renewable energy project isn’t welcome here!”.

The “clear and present danger” is to placate such ubiquitous opposition, planning and zoning boards have reluctantly approved these projects with their greatest attention placed on conditions that require renewable energy systems to be completely decommissioned upon exhaustion of their useful life (20-25 years). In addition, decommissioning agreements include returning the property to its “original condition”, with no further development of the property in perpetuity.

Often, I’ve seen more time spent discussing how and when these sustainable energy systems will be dismantled than how they’ll be constructed! In addition, and in complete defiance of State Statutes, many communities then pass ordinances or warrant articles that significantly restrict future renewable energy projects from being constructed in their communities. Talk about hypocrisy!

So, I ask, if all these renewable energy projects have decommissioning plans firmly in place, how are we to meet our federal, state, and local zero carbon emission goals by 2050? Just when we’d start making progress on achieving these goals, decommissioning provisions will kick in and cause massive amounts of renewable power to be taken off-line. Further, with provisions in place that restrict new energy projects from being rebuilt on these sites and land regulations that significantly restrict areas of new development, where are we to turn for additional renewable energy production?

I’ve been sounding the alarm to this paradox, but it often seems to fall on deaf ears. Maybe I’ll get more attention if I break into my own song next time…

I hear a train a comin’,

It’s rolling ‘round the bend.

That train’s headin’ straight for us,

and I don’t like how this ends…”

-->

Posted on July 19, 2022

Sand & Gravel vs Bedrock – Understanding Aquifer Solutions for Your Water Supply

Author: Jennifer Lambert, PG – Director of Environmental Services NH

A good water supply needs both sufficient quality and quantity – which can be complicated in New England. The first choice for water supply wells is overburden material, particularly sand and gravel. A “clean” (minimal finer-grained material) sand and gravel aquifer is a great source for large quantities of water. However, here in New England, we frequently encounter deposits that include finer material, which fills in the smaller pore spaces and reduces the amount of water that can be stored in a given volume and also the speed at which groundwater can move.

A sand and gravel aquifer can also be highly sensitive to contamination, however, because the same properties that allow for high flow for a drinking water well also allow contaminants to migrate with groundwater to that drinking water well. In addition to point sources of contamination (such as gas stations with potential fuel spills or hazardous waste sites), agriculture and densely populated residential areas with leach fields also have the potential to impact water supply with microbial contamination and excess fertilizer (the Walkerton, Ontario E. coli outbreak is an extreme example of this). Another issue for wells drawing from sand and gravel aquifers is the potential for them to tap into and deplete water from local wetlands and surface water bodies, causing potential damage to sensitive habitats.

Because a sand and gravel aquifer is both an excellent water source in terms of water production and may be impacted by (or may impact) near-surface conditions, these materials have been studied and identified. New Hampshire’s Granit geographic information system (GIS) has a layer identifying stratified drift (sand and gravel) aquifers, and Massachusetts’ Oliver GIS system identifies high yield and medium yield aquifers. These can be used as a starting point for determining if a sand and gravel water supply well should be considered.

Bedrock water supplies are more complicated, as most of the water will flow through specific fractures or fracture networks. Here in New England, our bedrock is frequently “mashed up” (you can see this on many of the road cuts, particularly southern portions of I-93 in New Hampshire), and therefore major water-bearing fractures are difficult to predict. Hydrogeologists use signs of fractures in the landscape (photolineaments) and surface geophysics to try and identify likely fracture zones, but the only way to confirm that a fracture or fracture zone will actually produce sufficient water is to drill test wells. Many of the residential wells in New England are bedrock wells because of the relative scarcity of sufficiently thick sand and gravel deposits; in this case, the driller will keep going until sufficient water is reached because there is not enough room to move to another area. This means that residential bedrock wells can be hundreds of feet deep.

Bedrock wells are generally well insulated from surface contaminants (although this is not true for all wells; shallow contamination can short-circuit the overburden and occur at surprising depths via near-vertical fractures) compared to sand and gravel wells. However, the bedrock itself can cause other issues: radon and naturally occurring metals such as iron, arsenic, and manganese that can both impact health and foul plumbing.

As our population increases and more people move into formerly rural areas, we will need to find additional water sources. Groundwater from both overburden (sand and gravel) and bedrock will likely need to be part of the solution, so it is important to consider both resources and their advantages and disadvantages in future planning.

-->

Posted on May 16, 2022

Four “Musts” When Evaluating PFAS at Your Site

Author: Krystina Lincoln, GIT – Project Geologist

Deciding to begin a Site Investigation for Per- and polyfluoroalkyl substances (PFAS) can be a worrisome proposition for any property owner or facility manager. Frequently referred to as “forever chemicals”, PFAS compounds are man-made compounds found in many consumer products, manufacturing processes, and aqueous film forming foams (AFFF) for firefighting. These compounds have been widely used since the 1950s and, while their gradual (and ongoing) phaseout has been underway for the last few decades, their presence and impact is far reaching. Further information on the background of PFAS compounds can be found in this ITRC Fact Sheet. This guide provides four “musts” when evaluating PFAS at your site.

Conduct a “Deep Dive” Into Historical Site Use

As PFAS compounds can have many sources, a good starting point is to conduct a “deep dive” into historical uses at the site and surrounding area. State/municipal records should be reviewed early on, including available Sanborn maps, to identify any past manufacturers, including metal finishing, textiles, carpeting, leather, paper products, automotive, industrial surfactants, and more that existed on the site. Dry cleaners may have processed PFAS-containing clothing, as well as any manufacturer of consumer products that applied stain or water repellants. AFFF could have been deployed during training or emergency response at fire stations, airports, military bases, or even at the location of a past building fire or vehicle accident. If the presence of PFAS is suspected at the site, potentially impacted areas of the site should be contained and identified. For instance, was fire training conducted in the rear parking lot? Is there a leach field that received discharge from a floor drain on the production floor?

Carefully Consider Your Analytical Methods

Given the low required reporting limits and complex nature of PFAS analyses available, commit sufficient time to read the regulations and to fully understand the analytical methodologies. At this stage, a great deal of proactive communication and planning with the analytical laboratory as well as other project stakeholders is critical. There are currently two widely available EPA approved methods for the analysis of PFAS compounds in drinking water (Methods 533 and 537.1), along with a third recently finalized method intended for non-drinking water matrices (SW-846 Method 8327). As SW-846 Method 8327 was only finalized in June 2021, many labs still do not have their Method 8327 certifications, but offering a Method 537 “Modified” approach for non-drinking water matrices. It’s important understand that each analytical method offers different, but overlapping, lists of PFAS compounds, so care must be taken to comply with the methods accepted by each State regulatory agency.

Must Avoid Cross-Contamination Risks In the Field

When conducting a PFAS-focused investigation at your site, it’s critical that any PFAS reported in the samples accurately represents the concentrations in site soil, groundwater, and/or surface water. Cross-contamination introduced during sampling will produce inaccurate results. PFAS compounds have been detected in many common products used during an environmental investigation including new clothing, rain gear, some sunscreens, water-proof field notebooks, and Polytetrafluoroethylene (PTFE)-based materials. While great care must be taken to prevent cross-contamination when collecting traditional environmental samples, an additional level of caution needs to be utilized when sampling for PFAS due to the presence of PFAS in many everyday items. PFAS containers should be collected before any others in a sampling suite, to minimize cross contamination. Frequent changes of nitrile gloves are necessary when handling any down well equipment and sample containers. Any suspected PFAS containing products should be kept far from the sampling area, or off-site if possible.

Off-site PFAS Sources Must Be Considered

After the sample results come in, a valuable exercise is to carefully evaluate potential offsite sources – if PFAS are found at your site. While not always conclusive, individual PFAS sources generate a different “signature”, or balance, of PFAS compounds. For example, AFFF use can create a PFAS signature with significant Perfluorooctanoic acid (PFOA), Perfluorooctanesulfonic acid (PFOS), and Perfluorohexanesulphonic acid (PFHxS), compared to other analyzed compounds. Even at the same AFFF impacted site, PFAS signatures may differ based on the “generation” of AFFF deployed in certain areas at the site. Older foams may contain higher relative amounts of PFOS when compared to PFOA. Metal plating facilities may generate PFOS heavy signatures. Signature evaluation may prove important when developing a conceptual site model in an industrialized area where multiple potential sources of PFAS are present. PFAS plumes can be longer than other contaminants like MtBE, BTEX, and chlorinated compounds, so the upgradient survey must keep this in mind.

-->

Posted on March 22, 2022

Why Don’t We Build Solar Arrays on All of New Hampshire’s Closed Landfills?

Author: Chris Nadeau, PE – Director of Commercial Services

Installing solar arrays on closed landfills sounds like a great idea, right? Introducing a beneficial reuse for an environmentally impacted property, especially a municipally owned abandoned lot for which there are few other valuable reuse options, seems like a practical solution all around.

However, as is often the case in life, what sounds great in theory is not always as sensible in practice.

Landfills are designed to minimize land area and maximize the ability to accept trash. To accomplish this, landfills fill vertically, which results in steep slopes and very little “flat” area on top. Most landfills are constructed with very steep slopes of 25-33%. Comparatively, if you’ve ever driven the Kancamagus Highway, its steepest slope is only 7%. This presents the first issue with constructing solar on landfill sites: solar panels need to be installed on surfaces with less than 10% slope.

In addition to slope requirements, the most efficient layout for solar arrays is placing them in long rows. These long rows of solar panels consist of table assemblies supported by steel racks or “legs” that are driven into the ground to prevent uplift from wind and downward pressure from the weight of the solar panel system and snow loads. When a landfill reaches its design capacity and is closed, an impermeable protective cap made up of soil and/or synthetic plastic lining is placed over its surface to shed precipitation. This impermeable layer would be perforated by the installation of traditional solar foundation legs, and therefore solar panel foundations on landfills must be constructed using specialized ballast – like concrete or rock filled baskets – that lay on the ground’s surface. These “landfill foundations” are significantly more complex and costlier to construct.

Furthermore, since most landfill caps are permitted by the New Hampshire Department of Environmental Services (NHDES) Solid Waste Bureau, in order to make any modifications to a landfill, solar developers must file a “Modification Permit” which requires a complete analysis of the foundation loads on the cap. This analysis is required to prevent differential settlement of the cap system and to demonstrate that the arrays will not slide off the side of the landfill. Additionally, solar developers need to demonstrate that the application of impervious solar panels will not adversely affect the landfill cap by introducing higher stormwater runoff rates that would cause erosion of the landfill surface. In short, these analyses often reveal that steep landfill slopes will not adequately support solar arrays.

If slope and foundation hurdles aren’t enough to deter a solar developer from pursuing a landfill location, further requirements for the actual construction just might. Developers must analyze and ensure that the weight of construction equipment driving over the landfill cap during installation of solar arrays does not adversely impact the impervious cap material. If that can’t be assured, then it’s “lights out” (quite literally) for construction of the solar array. Even the wiring between panels poses an issue: it must be run above ground instead of buried like a typical array, in order to avoid penetrations into the cap liner system. This specialized wiring adds additional costs and complexity to overall maintenance of the system after it is built.

Speaking of wiring, all solar projects – regardless of whether or not they are located on a landfill – must be located in close proximity to a 3-phase electrical distribution line. This allows the solar panel system to be connected to an electrical substation that has the capacity to allow additional load. Many of our municipal landfills are located in more rural areas that lack available nearby utility infrastructure required to connect solar arrays to the electrical grid.

Recognizing that a solar project has to produce enough power to offset all of these additional costs for engineering, construction, and interconnection, it easy to see how, although placing solar on our landfills may seem like a great concept, the multitude of constraints can (and often do) kill these highly specialized projects.

-->

Posted on October 7, 2021

Manganese and Arsenic in New Hampshire’s Drinking Water Supplies – What You Need To Know

Author: Jim Vernon, PhD, PG, CG – Director of Water Supply Services

Manganese and arsenic are metals that are commonly found in New Hampshire’s drinking water wells. Commonly referred to as “contaminants”, these metals typically derive from natural sources. (Manganese and arsenic that are elevated due to human-caused contamination or treatment for other contaminants is a subject for a future article.)

Concentrations of both manganese and arsenic in New Hampshire groundwater vary greatly, depending on many factors including the type of underlying bedrock and other water chemistry factors, such as the pH (measure of water’s acidity) and oxidation/reduction potential. Elevated levels of one metal does not necessarily indicate elevated levels of the other. Both metals can be found in bedrock wells, while manganese is also found in some dug wells and screened wells tapping overburden groundwater. Shallow wells near swamps have a greater likelihood of elevated manganese than wells not located near swamps or wetlands, but there are many exceptions.

Long considered an aesthetic parameter (possibly staining bathroom fixtures or laundry), manganese is now known to present health risks at higher concentrations, including neurotoxic effects on infants and children. Manganese concentrations in drinking water are subject to a series of standards that can be measured in micrograms per liter (ug/L), which is equivalent to parts per billion (ppb). Here are the current New Hampshire standards for manganese:

- Secondary (aesthetic) drinking water standard = 50 ug/L; not a health standard; established by EPA in 1974

- EPA Health Advisory for Infants = 300 ug/L

- NH ambient groundwater quality standard (AGQS) = 300 ug/L as of December 2020 (formerly 840 ug/L). This is a health-based standard for both drinking water and water that is discharged to the ground.

Depending on the groundwater chemistry in a well, manganese can either be dissolved in the water or suspended as particles or colloids. The New Hampshire Department of Environmental Services (NHDES) advises testing for both dissolved manganese and total manganese before selecting a water treatment option. For more information, consult NHDES Fact Sheets on manganese and on water treatment, available on the NHDES website.

Arsenic is potentially more dangerous at lower concentrations in groundwater than manganese. Arsenic concentrations are higher in some parts of NH than others, depending on bedrock type and other factors. Arsenic can occur in two forms in well water: As-III (Arsenite) or As-V (Arsenate). Long-term consumption of water with elevated arsenic increases the risk of certain cancers and other disorders; additional risks are found in infants who consume water with elevated arsenic. For additional information, consult NHDES Fact Sheet DWGB-3-2, available on the NHDES website.

Research has determined that lower concentrations of arsenic can produce health risks, so standards have progressively lowered (become more stringent) over the years:

- 1975 – 2001: 50 ug/L; EPA standard for Public Water Systems

- 2001 – 2021: 10 ug/L; still the EPA standard in many states for Public Water Systems

- July 2021 – present: 5 ug/L; new standard passed by NH Legislature for Public Water Systems

Water tests are recommended for private wells, particularly bedrock wells. If the result is greater than 5 ug/L NHDES recommends testing for the specific types of arsenic (As-III vs As-V) because treatment methods vary depending on which type of arsenic is present. For more information, see NHDES Fact Sheet DGWB-3-2.

-->

Posted on September 21, 2021

Written Safety Programs – Does Your Business Need One?

Author: Jeremy Wherren, CSP, CHMM, CMQ/OE – EHS Management Practice Leader

With all of the responsibilities required to run a business, it can be difficult to think about (let alone implement) a written health and safety program that addresses all of the applicable Occupational Safety and Health Administration (OSHA) requirements relevant to your industry. Or, worse yet, an employee filed a complaint and an OSHA inspector has just shown up in the lobby requesting to conduct an inspection of your facility. Are you ready? Do you know what’s required of you to maintain compliance?

Even if your company checks all of the boxes when it comes to performing work safely and conducting training for your employees, do you have the necessary written programs in place to help maintain compliance? OSHA regulations are ever-changing: whether by revision of existing requirements or publication of brand-new regulations, and it can be difficult and overwhelming to both understand and keep up with exactly what’s required for your business.

The OSHA website summarizes the following standards requiring a written program, which are commonly applicable to businesses depending on their operation. Does your company meet any of these standards?

- Hazard Communication – If employees may have exposure to chemicals in the workplace – OSHA 29 CFR General Industry Regulation 1910.1200

- Emergency Action Plan – If your facility has more than 10 employees – OSHA 29 CFR General Industry Regulation 1910.38

- Fire Prevention Plan – If your facility has more than 10 employees – OSHA 29 CFR General Industry Regulation 1910.39

- Control of Hazardous Energy (Lock Out-Tag Out) – If your employees service or maintain machines or equipment that could start up unexpectedly or release hazardous energy – OSHA 29 CFR General Industry Regulation 1910.147

- Personal Protective Equipment (PPE) – Employers must perform an assessment of each operation in their workplace to determine if their employees are required to wear PPE – OSHA 29 CFR General Industry Regulation 1910.132

- Respiratory Protection – If employees are required under the regulation to wear a respirator – OSHA 29 CFR General Industry Regulation 1910.134

- Hearing Conservation – If employees are exposed to excessive noise > 85 decibels (rule of thumb: conditions that make normal conversation difficult) – OSHA 29 CFR General Industry Regulation 1910.95

- Bloodborne Pathogens – If employees may be exposed to blood or bodily fluids as part of their assigned duties – OSHA 29 CFR General Industry Regulation 1910.1030

This list is by no means all-inclusive, and some industries have additional written program requirements, such as construction under 29 CFR 1926. And it’s not just federal OSHA regulations that need to be verified for business – there are 22 states with their own OSHA-approved plans that cover both private and local government workers, and another 6 states with plans that cover just local government workers (the remaining states are covered by federal OSHA).

Several states also have their own specific requirements for health and safety related programs, which may or may not be under an OSHA-approved plan. For example, the New Hampshire Department of Labor requires a Joint Loss Management Committee or “safety committee” in a workplace with more than 15 employees, as well as a written safety program with specific elements.

Employee safety is a genuine priority for any business leader worth their salt, but even the most well-intentioned owners and professionals may not know what they don’t know. A qualified Environmental, Health, and Safety (EHS) consultant can provide guidance and understanding to businesses considering the applicability of EHS programs within their operations. An investment in a written health and safety plan is an investment in your employees, your clients, and your business. And often, as the saying goes, “what gets written down, gets done”.

-->

Posted on September 7, 2021

Author: Chris Nadeau, PE – Director of Commercial Services

How many times have you heard “All the good land has been developed and now we’re just left with the difficult stuff!” or “If it was easy, it would have already been developed!”? Oftentimes that’s the case, but consider this: as our appetite for different types of development and expanding municipal growth boundaries change, so does the possibility of finding land that is appropriate and relevant for the type of development you’re pursuing.

The first step in deciding whether a piece of land is worth your time and money to develop is to establish your goals. What are you trying to accomplish? What will your ideal site layout look like (size of buildings, open space, parking, etc.)? Do you need high visibility, or can you work with something off the beaten path? Not only should you set your goals, but you need to be able to communicate your goals clearly with others. Know exactly what you want, but be flexible enough to allow for modifications.

The next step is to find some properties that will meet some or most of your goals. Once you find something, you need to go through a series of due diligence steps (“kicking the tires”) to determine whether a property is worth pursuing further before you start investing large sums of money. Following are some common steps to take while in the due-diligence phase.

- Review available Geographic Information System (GIS) mapping. Many municipalities have on-line GIS mapping – find out who owns the property, look at topography, find out abutting uses, zoning, critical habitat, and natural resources.

- Review Municipal Land Use Regulations including zoning ordinance, site plan regulations, master plan, and subdivision ordinances. Is your desired use allowed? What are the dimensional constraints for a particular zone? Are there architectural and landscaping standards? Most, if not all, of this information can be found on the municipality’s website.

- Before you jump in the car, review current and historical aerial photos on Google Earth. Pay particular attention to ground cover, past development, whether there are municipal utilities (sewer, water, gas, storm drainage, electrical and telecommunications infrastructure), and what abutting land is being used for. Hint: if the ground cover is brown year-round, it might be a wetland!

- Review the State environmental databases to determine whether the property has any past or current environmental concerns.

- Perform a query with the State Division of Historical Resources to find out whether there are records of archaeological or culturally significant sensitive areas in proximity to your project.

- Perform a query with the State department responsible for overseeing critical animal and plant habitat to see if there are records of threatened or endangered species or critical habitat in the vicinity of your project.

- Contact the Department of Transportation (if the site is on a State Highway) or the local Highway Department (if it is on a local roadway, or within an urban compact zone). Will they grant an access permit? Will you be required to make roadway improvements for the use you are proposing? Are there any long-range plans to reconstruct or rehabilitate the roadway? Is the roadway under a pavement moratorium?

- Talk to a local. It could be a local real estate agent, a surveyor, an engineer, or just a friend who lives in the town. This way, you can get a sense for local flavor – whether the Town is in favor of development or whether they will fight you. Be specific about the use (retail, office, residential, etc.). Less than 5 years ago, residential development was often met with strong resistance, while commercial development was welcomed with open arms. Today, the resistance is very different. The most attractive development for municipalities is “mixed use” where you have commercial and residential usage within the same development. Today, denser is often better, but again, it depends on the municipality. It pays to ask around and get a feeling for your community’s preferences.

- Jump in your car and drive around. Perform a windshield inspection of the property to look at site access; natural features including topography, soils, and vegetation; obvious environmental issues; proximity to municipal services; and overall “curbside appeal” of the property.

At this point, you haven’t spent a dime (except for some gas money). If everything passes “the straight face test”, it might be time to hire an expert to verify or clarify your findings. If you do nothing else, spend a few hundred dollars to have a wetland scientist or land use expert perform a site reconnaissance and look for “show-stopper” issues like wetlands. You won’t regret this because nothing can be more detrimental to the development of your property than the presence of wetlands. Trust me, after 30 years in this business, I still get surprised.

For a very reasonable few thousand dollars, you can hire a land consultant or engineer to do much of this work on your behalf. Often, this low fee carrot is a promise to the expert of an actual project with more substantial fees and the establishment of a long-term relationship with you as their client. The end product can be as simple as an email summary, or a more in-depth “fatal flaw” report with a conceptual site plan that you can take to the local Town officials or Land Use Board to get their feedback on what you are proposing.

Contrary to the naysayers, there is still good land out there ready to be developed. It’s just waiting for you to make that call. By following this checklist, you’ll find the right site for the right development.

-->

Posted on August 31, 2021

Author: Tim Andrews, PG – Senior Project Manager

Redevelopment of a previously developed property or a Brownfields site requires a lot of planning and investment. It’s easy to focus on tangible considerations, such as the planning for the redevelopment, construction permitting requirements, and the cost for construction. But what about the less obvious considerations that can pose a significant environmental risk to you, as the future owner of the property, and to your investment? A good redevelopment plan includes completion of appropriate due diligence up front to assure the less obvious environmental risks and concerns are identified and included in the big picture for the developer and all stakeholders.

UNDERSTANDING THE RISKS